High costs of replacing large bearings

To keep maintenance budgets low, many customers look for alternatives to replacing bearings with brand-new ones.

#5

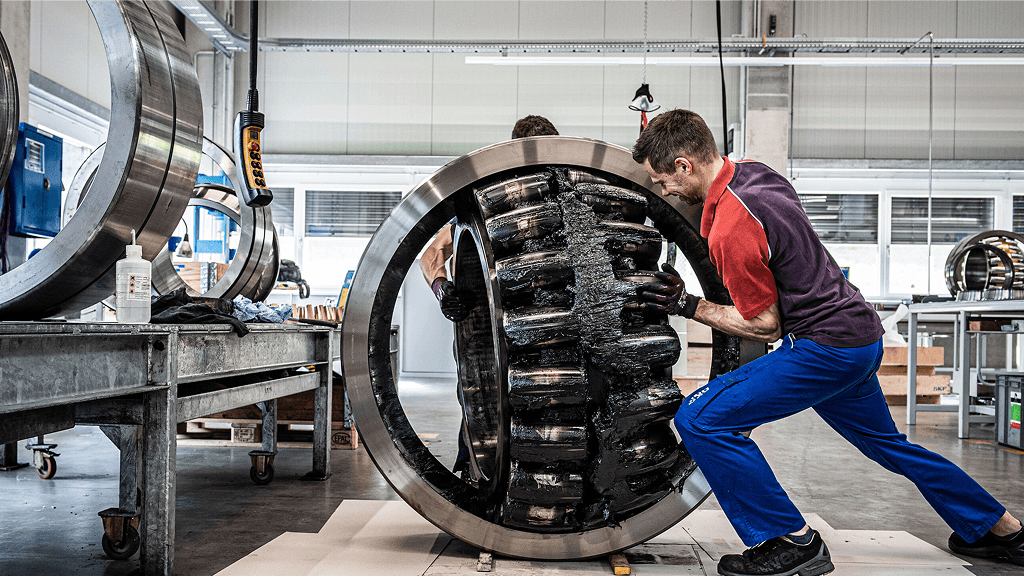

Unlock the full potential of your bearings with remanufacturing

Many of the bearings installed in rolling mills can be remanufactured, sometimes twice, depending on their condition. Remanufacturing a bearing is a way to save cost, improve lead times, reduce CO₂ emissions, and significantly extend the bearing service life.

Extend service life

With SKF Remanufacturing, you can unlock the built-in potential of your bearings and restore their full useful life, using fewer resources, and with a shorter delivery time than new bearings. But with the same SKF performance. You get reliable remanufactured bearings according to SKF standards, documented CO₂ emissions reduction, and SKF warranty with the same conditions and duration as for new bearings.

Keep costs and CO₂ down

The remanufacturing process is less energy-intensive and requires fewer process steps and less new material than producing new bearings. This means a cost reduction of up to 50% compared to new bearings and an emission reduction of up to 90% every time you remanufacture a bearing.

Remanufacturing: positive impact on service life

- Damage occurs

- First remanufacturing*

- Second remanufacturing*

- Potential service life without remanufacturing

- Potential service life after first remanufacturing

- Potential service life after second remanufacturing